“WHAT EXTRACTION METHOD DO YOU USE?”

This is a very common FAQ. Rightfully so. Consumers should be concerned with how their CBD products of choice are produced, especially in today’s market. Extracts are most commonly made either by processing the flower with a hydrocarbon like butane or propane (know as Butane Hash Oil or BHO <- See the connection here? ????), pressurizing the material with carbon dioxide (CO2) or soaking it with ethanol. In this blog, we’ll take the time to review our method of choice, hydrocarbon extraction, bring to light some of its misconceptions and introduce a few other common methods.HYDROCARBON EXTRACTION

An article written by Lindsay Maharry, “Debunking the BHO Stigma: A Scientist’s Take on Butane Hash Oil vs. CO2 Extraction” does a good job at shining a light on how unsafe practices engaged in by kids changed the perception of this extraction method. (I highly recommend you read it!) When in fact, this method, if done correctly, is completely safe. Hydrocarbons are non-polar, meaning they bind to the more fat-soluble components of the plant (cannabinoids and terpenes only) to gently extract compounds from cannabis plant material. The result is a higher purity extract and the only product that truly resembles the plant from which it came.WHAT ARE HYDROCARBONS?

Hydrocarbons are a classification of organic compounds, consisting of carbon and hydrogen, formed from the compression of animal and plant remains over long periods of time. The most common hydrocarbons include butane, propane and hexane. Hydrocarbons are also powerful organic solvents – substances capable of dissolving or dispersing other substances. They’re most commonly used in natural food flavorings, soybean oil, vegetable oil, and many other food products which are consumed daily. Fun fact: Hydrocarbons like propane and butane are recognized as safe by the FDA and have been used since the 1970s for food production and extractions. Menu items like crème brulee and flan are finished with butane torch to crust it. Many will host barbeques while cooking their food with a propane grill. And let’s not forget the smokers who light up with butane lighters!WHY BUTANE?

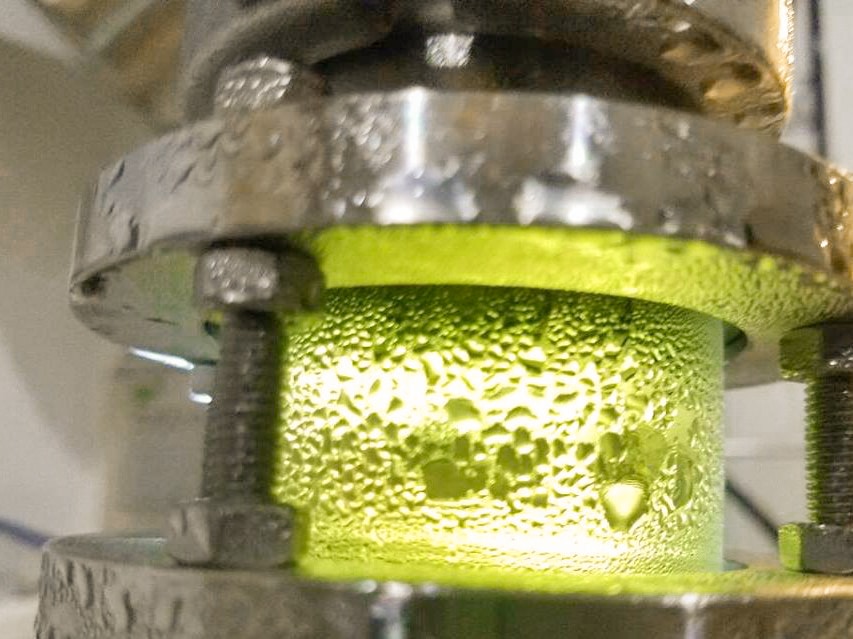

Butane is a popular solvent in the cannabis world. It’s a non-polar, Class 2 liquefied gas, with a low boiling point of 31.1°F and evaporation point of 33°F. In cannabis extraction, this is important because it allows for the cold-boiling of any leftover solvent from the concentrate, preserving cannabinoids and temperature-sensitive terpenes, resulting in a high quality product free from residual solvents.

OTHER COMMON EXTRACTION METHODS

CO2: CO2 extraction is a process that uses pressurized carbon dioxide to pull desired cannabinoids from the plant. Its vapor pressure is so high the CO2 simply disappears, leaving no potential for residual. However, this pressure is harsher on the plants and strips the terpenes during the process. In Maharry’s article, she goes further and explains the appeal of this process to manufacturers in the industry, stating it allows companies “to get away with running poor quality flower” due to the fact they are producing a homogenous product. (In her case, she focuses on THC only, whereas what we see in the hemp industry is CBD only.) Here is a link to a great blog about The most common CBD extraction methods.

Ethanol: In this process, the solvent, Ethanol, is passed over the plant material in order to dissolve the cannabinoids in the plant. Because ethanol is what is called a “polar” solvent, it will want to bind to the water-soluble components of the plant. The result is a less pure, generally less potent, end product that needs further refining and therefore has limitations in making a truly pure, full spectrum extract.

Check out the video in the link below for more info on CO2 vs. Solvent-Based Extraction: https://precisionextraction.com/2019/06/solvent-based-extraction-vs-co2-extraction/

Our visit our Podcast page and listen in as we discuss the most common methods of extraction in Episode 11

Recent Comments